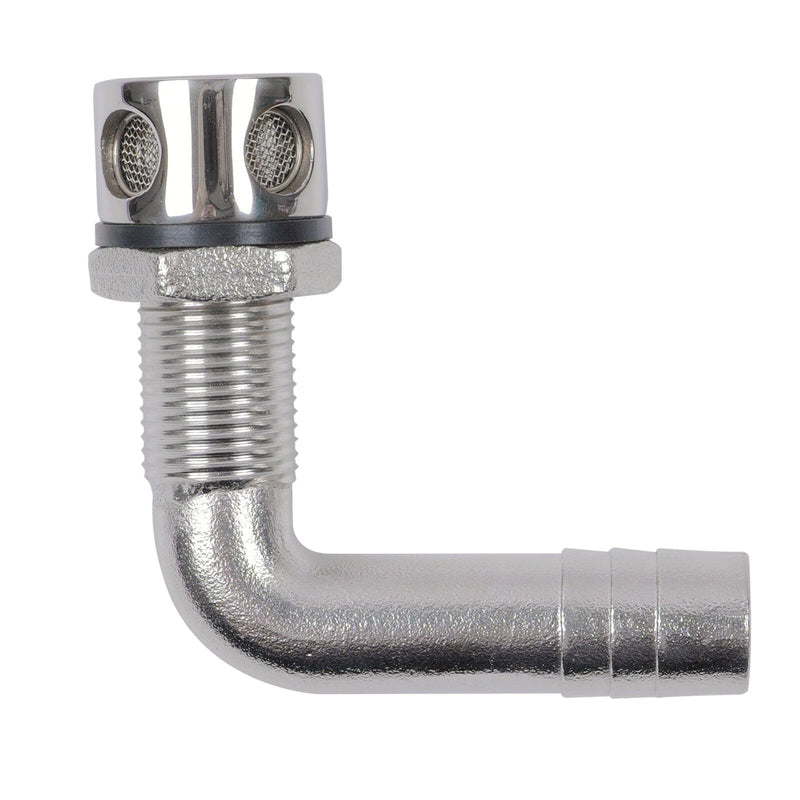

316 Stainless Steel Air Vent Fuel Tank Breather Threaded Bulkhead Screened 90 Degree Hose Outlet

Free returns on all eligible orders

You have 30 days to request a return. All sale items are final sale.

Product Overview

This is a 316 stainless steel fuel tank breather designed for reliable venting where corrosion resistance and clean airflow matter. Machined from marine grade 316 stainless, the unit features a threaded bulkhead fitting, locking nut, and a 90 degree barbed outlet for neat hose routing. The polished finish resists salt and fuel vapors while the screened vent prevents debris ingress and promotes safe, consistent tank venting for marine and industrial fuel systems.

Key Features

316 stainless steel construction

Marine grade material resists pitting and corrosion in saltwater and fuel-exposed environments.

Threaded bulkhead fitting with locking nut

Secure through-panel installation with gasket or sealant provides a watertight, vibration-resistant mount.

90 degree barbed outlet for hose routing

Low profile elbow directs vent hose neatly along the hull or equipment and accepts standard hose with clamp.

Polished finish for low maintenance

Smooth surface sheds grime and simplifies cleaning for long-term reliability.

Robust machining and seal integrity

Precision threads and solid construction reduce the chance of leaks under vibration and movement.

Specifications

Material 316 stainless steel

Finish Polished 316 stainless finish

Design Threaded bulkhead breather with locking nut 90 degree barbed outlet

Hose connection Barbed tail accepts hose with clamp check product option for exact barb diameter

Environment Designed for marine fuel tanks, diesel tanks, and outdoor industrial exposure

Applications

Fuel tank breather for boats and yachts

Auxiliary fuel and diesel tank venting

Oil sumps and small engine fuel tanks

Portable fuel storage and industrial tanks that require screened venting

Installation and Maintenance

Install with a suitable gasket or marine sealant and tighten the locking nut to recommended torque. Secure hose to the barbed outlet with a corrosion resistant clamp. Rinse with fresh water after heavy salt exposure and inspect the screen periodically for blockages or corrosion. Replace the breather if the threads are worn, or if sealing integrity is compromised.

Note: Due to manual measurements, please allow for slight tolerance in size.